hi guys

so finally a update

i'm sorry it has taken me so long but work was a bit crazy this week and i had some long days so i didn't get to do a lot of building

but the building stages are done

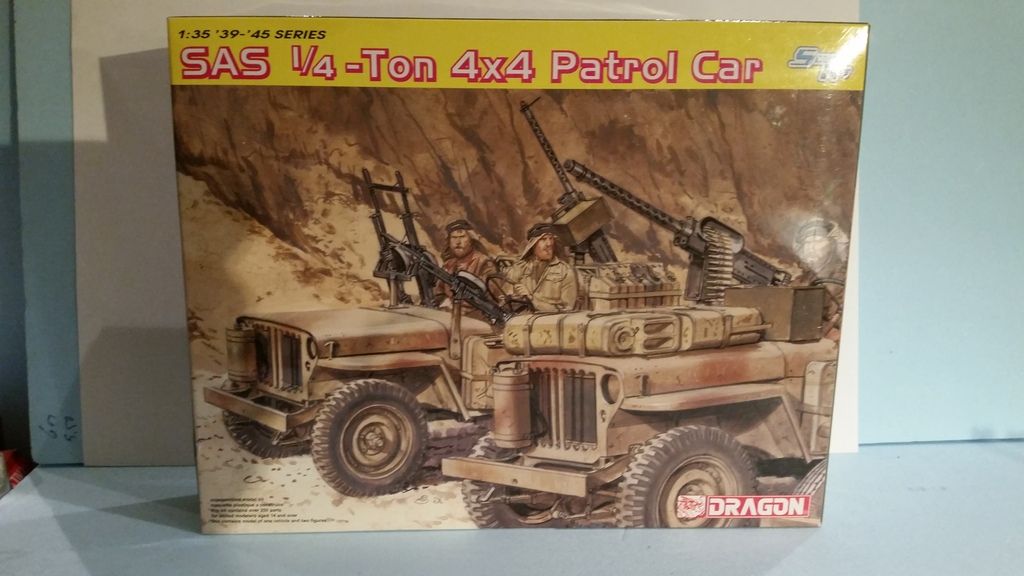

but before i go to the build lets start with some background information about these SAS Jeeps

let's start with with the base , the Jeep itself

Advances in early 20th century technology resulted in widespread mechanisation of the military during World War I. The United States Army deployed four-wheel drive trucks in it, supplied by Four Wheel Drive Auto (FWD) and the Thomas B. Jeffery Company. By the eve of World War II the United States Department of War had determined it needed a light, cross-country reconnaissance vehicle.

Anxious to have one in time for America's entry into World War II, the U.S. Army solicited proposals from domestic automobile manufacturers for a replacement for its existing, aging light motor vehicles, mainly motorcycles and sidecars, and some Ford Model Ts.[4][5] Marmon-Herrington presented five 4x4 Fords in 1937, and American Bantam delivered three Austin roadsters in 1938. Recognizing the need to create standard specifications, the Army formalized its requirements on July 11, 1940, and submitted them to 135 U.S. automotive manufacturers.

By now the war was under way in Europe, so the Army's need was urgent and demanding[citation needed]. Bids were to be received by July 22, a span of just eleven days. Manufacturers were given 49 days to submit their first prototype and 75 days for completion of 70 test vehicles. The Army's Ordnance Technical Committee specifications were equally demanding: the vehicle would be four-wheel drive, have a crew of three on a wheelbase of no more than 75 in (1,905 mm) - that was later upped to 80 in (2,032 mm) - and tracks no more than 47 in (1,194 mm), feature a fold-down windshield, 660 lb (299 kg) payload and be powered by an engine capable of 85 lb·ft (115 N·m) of torque. The most daunting demand, however, was an empty weight of no more than 1,300 lb (590 kg).

Initially, only two companies entered: American Bantam Car Company and Willys-Overland Motors; Ford Motor Company joined the competition later. Though Willys-Overland was the low bidder, Bantam received the bid, being the only company committing to deliver a pilot model in 49 days and production examples in 75. Under the leadership of designer Karl Probst, Bantam built their first prototype, dubbed the "Blitz Buggy" (and in retrospect "Old Number One"), and delivered it to the Army vehicle test center at Camp Holabird, Maryland on September 23, 1940. This presented Army officials with the first of what eventually evolved into the World War II U.S. Army Jeeps: the Willys MB and Ford GPW.

Since Bantam did not have the production capacity or fiscal stability to deliver on the scale needed by the War Department, the other two bidders, Ford and Willys, were encouraged to complete their own pilot models for testing. The contract for the new reconnaissance car was to be determined by trials. As testing of the Bantam prototype took place from September 27 to October 16, Ford and Willys technical representatives present at Holabird were given ample opportunity to study the vehicle's performance. Moreover, in order to expedite production, the War Department forwarded the Bantam blueprints to Ford and Willys, claiming the government owned the design. Bantam did not dispute this move due to its precarious financial situation. By November 1940, Ford and Willys each submitted prototypes to compete with the Bantam in the Army's trials. The pilot models, the Willys Quad and the Ford Pygmy, turned out very similar to each other and were joined in testing by Bantam's entry, now evolved into a Mark II called the BRC 60. By then the U.S. and its armed forces were already under such pressure that all three cars were declared acceptable and orders for 1,500 units per company were given for field testing. At this time it was acknowledged the original weight limit (which Bantam had ignored) was unrealistic, and it was raised to 2,160 lb (980 kg).

For these respective pre-production runs, each vehicle received revisions and a new name. Bantam's became the BRC 40. Production began on March 31, 1941, with a total of 2,605 built up to December 6. As the company could not meet the Army's demand for 75 Jeeps a day, production contracts were also awarded to Willys and to Ford.

After reducing the vehicle's weight by 240 pounds, Willys changed the designation to "MA" for "Military" model "A". The Fords went into production as "GP", with "G" for a "Government" type contract and "P" commonly used by Ford to designate any passenger car with a wheelbase of 80 in (2,032 mm).

By July 1941, the War Department desired to standardize and decided to select a single manufacturer to supply them with the next order for 16,000 vehicles. Willys won the contract mostly due to its more powerful engine (the "Go Devil"), which soldiers raved about, and its lower cost and silhouette. The design features the Bantam and Ford entries had which were an improvement over Willys' were then incorporated into the Willys car, moving it from an "A" designation to "B", thus the "MB" nomenclature. Most notable was a flat wide hood, adapted from Ford GP.

By October 1941, it became apparent Willys-Overland could not keep up with the production demand and Ford was contracted to produce them as well. The Ford car was then designated GPW, with the "W" referring to the "Willys" licensed design. During World War II, Willys produced 363,000 Jeeps and Ford some 280,000. Approximately 51,000 were exported to the U.S.S.R. under the Lend-Lease program.

A further roughly 13,000 amphibian jeeps were built by Ford under the name GPA (nicknamed 'Seep' for Sea Jeep). Inspired by the larger DUKW, the vehicle was produced too quickly and proved to be too heavy, too unwieldy, and of insufficient freeboard. In spite of participating successfully in the Sicily landings in July 1943, most GPAs were routed to the U.S.S.R. under the Lend-Lease program. The Soviets were sufficiently pleased with its ability to cross rivers to develop their own version of it after the war, the GAZ-46.

and the specs

Type

1⁄4 short ton (0.22 long tons; 0.23 t)[1] 4x4 utility truck

Place of origin United States

Production history:

Manufacturer

Willys-Overland (MB)

Ford (GPW)

Number built

MB: 359,489 (willys)

GPW: 277,896 (Ford)

Specifications (MB and GPW same due to the standard specs requested by the US Department of Defence)

Weight 2,453 lb (1,113 kg) empty

Length 132 1⁄4 in (3.36 m)

Width 62 in (1.57 m)

Height 69 3⁄4 in (1.77 m)[

Engine Willys Go Devil engine (134.2 cu in (2,199 cc) gasoline powered )

Transmission 3 spd. x 2 range trf. case

Suspension Live axles on leaf springs

Fuel capacity 15 US gal (12.5 imp gal; 56.8 L)

Operational range 300 mi (482.8 km)

Speed 65 mph (105 km/h)

so that is the basic Jeep but the SAS version is different as it carries weapons and a huge load of equipment and fuel and water jerrycans

allthough this added weight affects the range it can go about 200 km (125 mi) further on each jerrycan of fuel is carries

this means that the SAS increased the range for about 3 to 4 times to well over 1200 km

and now for some specs on the SAS version

weapons :

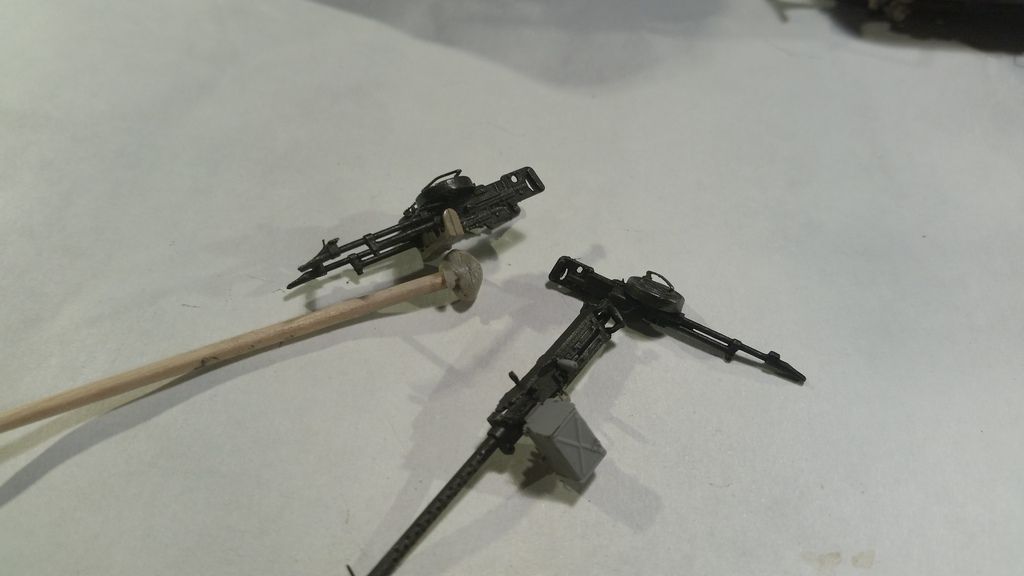

3 Vickers K drum feed machineguns (1 seperate and a double mounted)

1 Browning M2 aircooled 0.50 Cal. (12.7mm) machine gun

the positions could be different on the vehicles as some had the double vickers guns on the high mount in the rear and the Browning in front of the passengers seat and others had this switched around with the BMG in the back and the double Vickers in the front

Tools :

basicly non as the Original tools of the Jeep where removed but the crews replaced the shovel as that was needed in the dessert

also so small tools would be present to repair the vehicle in the field and ofcourse the skidplates they added for the times they would get stuck in the sand

Stowage :

this consists of jerrycans most often 10 or kore containing fuel (gasoline) and water

other things present in the vehicles would be personal equipment of the crew like their normal issued items and fire arms

this is mostly gathered information from Wikipedia and by simply looking at photo's of the real vehicles

here are some photo's of the real ones

this is ofcourse one of the best known photo's of the SAS in North Africa

this shows 3 of the jeeps along with the unit commander Colonel David Sterling who was closely involved with the beginning of the unit and was the first commander

same photo but enlarged

you can see the large amount of paintchipping on the jerrycans and jeep

this vehicle shows the weapons in a different position then i have done with the kit

the large 0.50 cal is in the front position in front of the passenger seat

the gun has the large 200 round ammo box attached to it while they can also mount smaller 100 and 50 round boxes

yet another layout of the guns

this vehicle lacks the Vickers k mg for the driver and only has the double mounted and a single one in the rear

you can also see that this vehicle had to have it's right front wheel replaced as it has a different thread pattern then the stock tyre on the left side of the vehicle

not a North Africa jeep but still a SAS jeep

this is the later design that was used in Western Europe

the large amount of jerrycans are replaces by 2 fueltanks that are placed in the back of the vehicle

it also has small windscreens for the driver and the gunner

and that was my information bit for now

i will try to find some information about the SAS and the war in the northern part of Africa for the next update

and now for the build

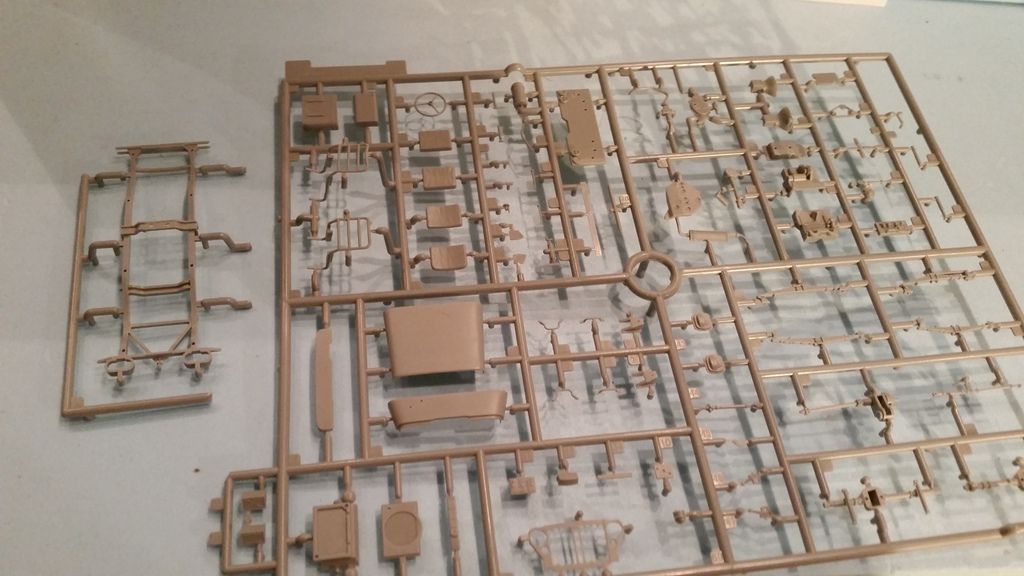

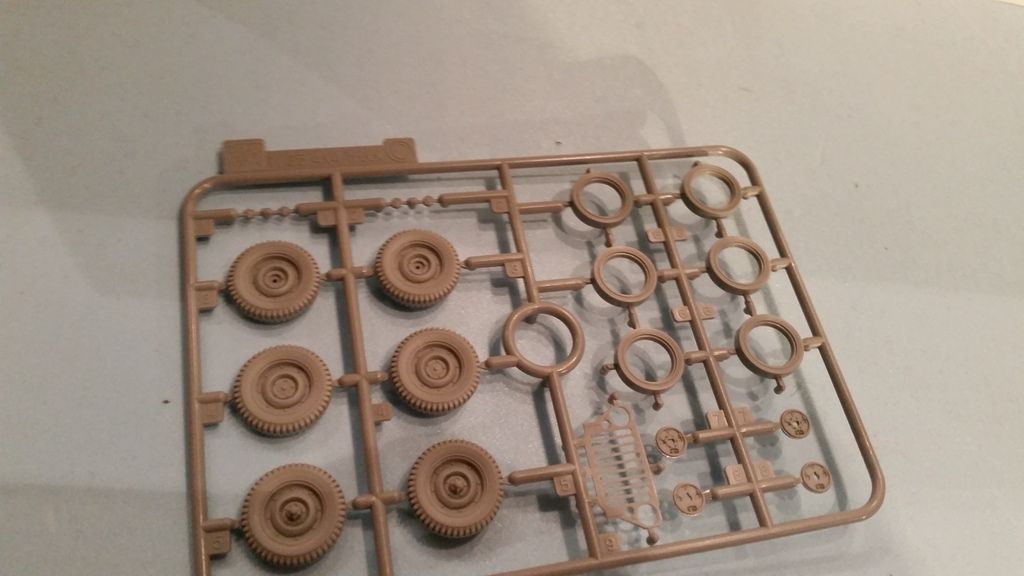

the build starts with the wheels

you have the option of 2 styles of tyres but i went for the regular style that was used the entire war

these are the front wheels , rear and spare (from top to bottom)

next where the axles

the axles where fitted to the chassis aswell as the bottom protection plate wich covers the transmission box

then you get to build the "go devil"engine wich is nicely detailed and only misses the spark plug wire

but because i will make this kit with the hood closed it will be hidden so i didn't spend the time to add details to it

the radiator with the lights molded on

i will add the clear parts later once evrything is painted

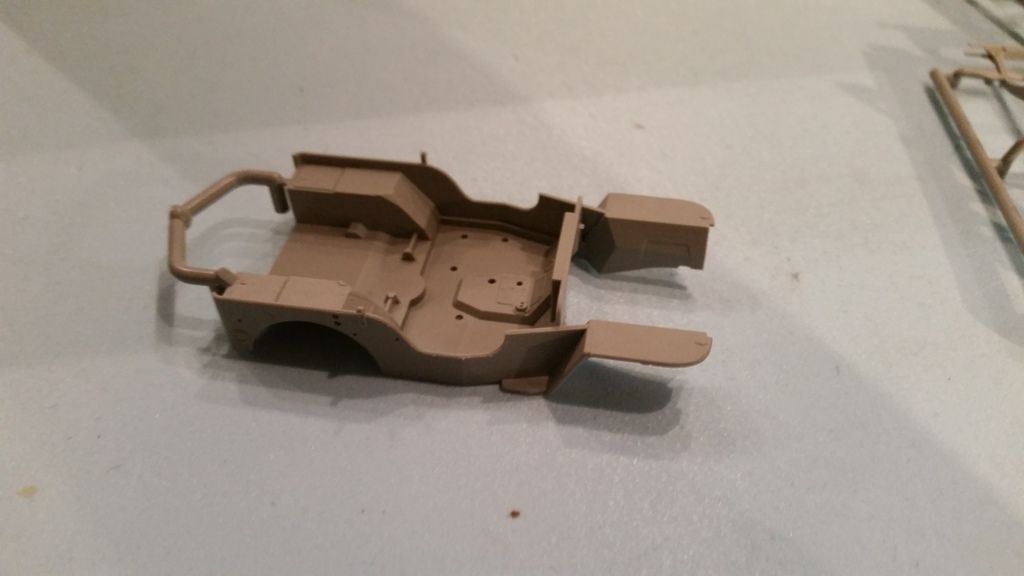

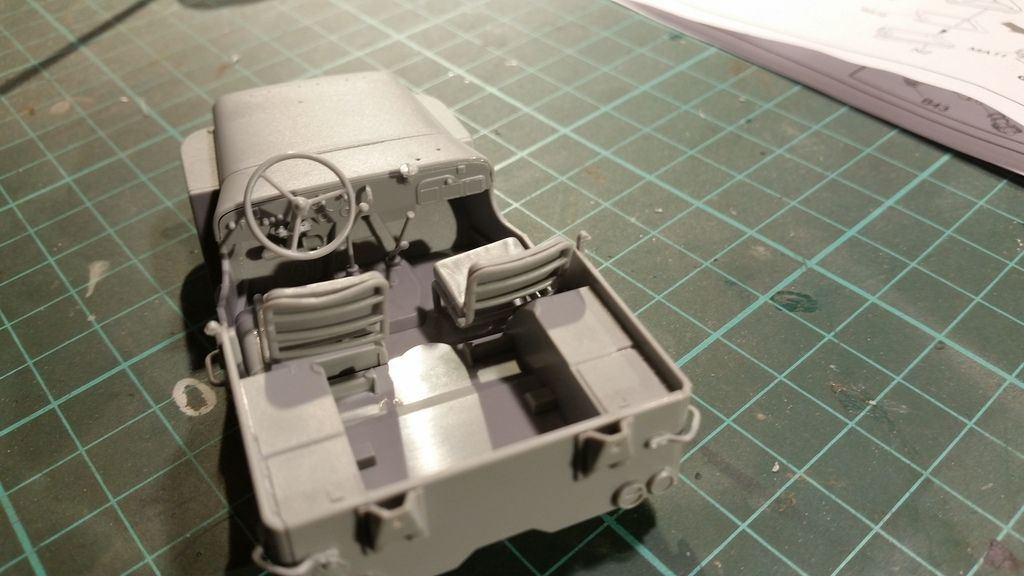

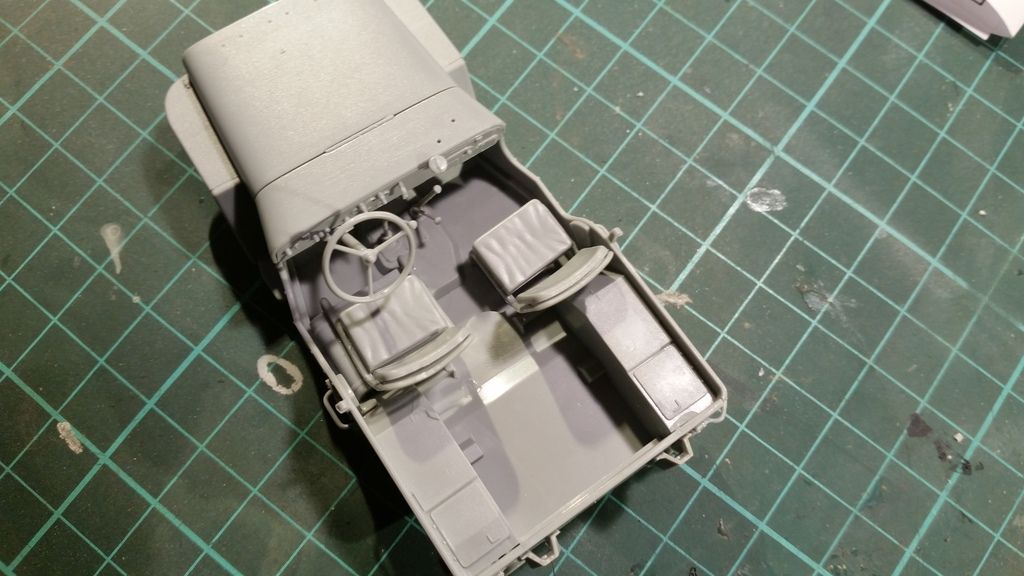

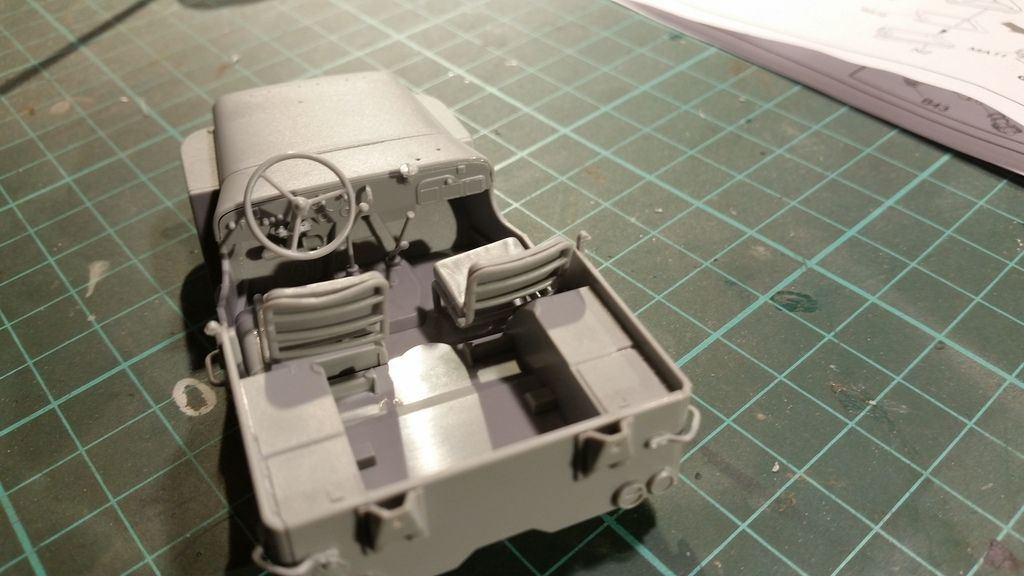

the body tub of the jeep with the first details added like the battery box

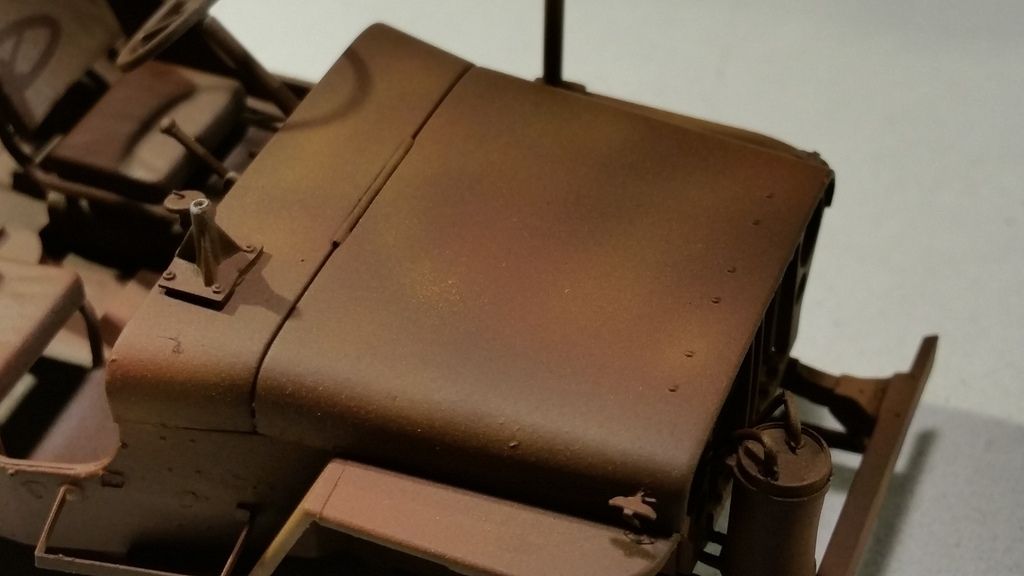

the hood and instrument panel

using 0.5mm leadwire i added some tubing to the condenser that goes on the front of the jeep

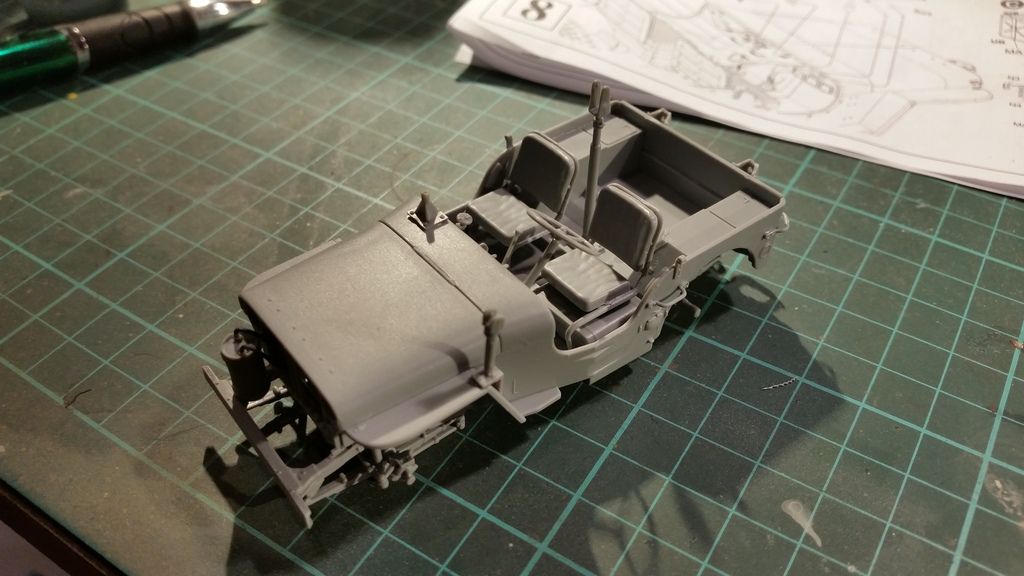

everything was then added to the body

some exterior details where added

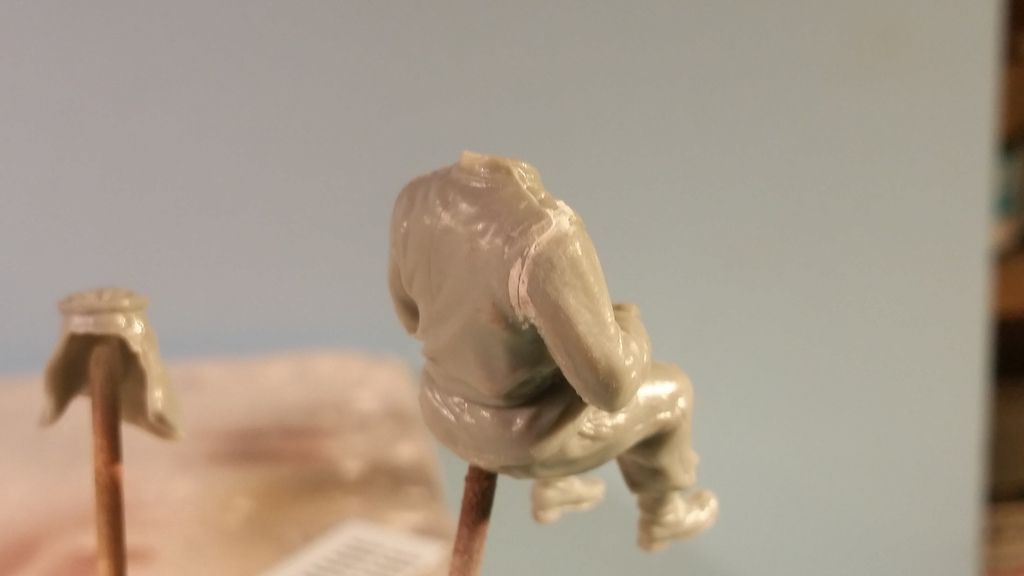

i then added the seats

i wasn't happy with them as the holes in the bottom are 1 mm or even bigger

the supports of the seat are not even half as big so there where some big holes to fill

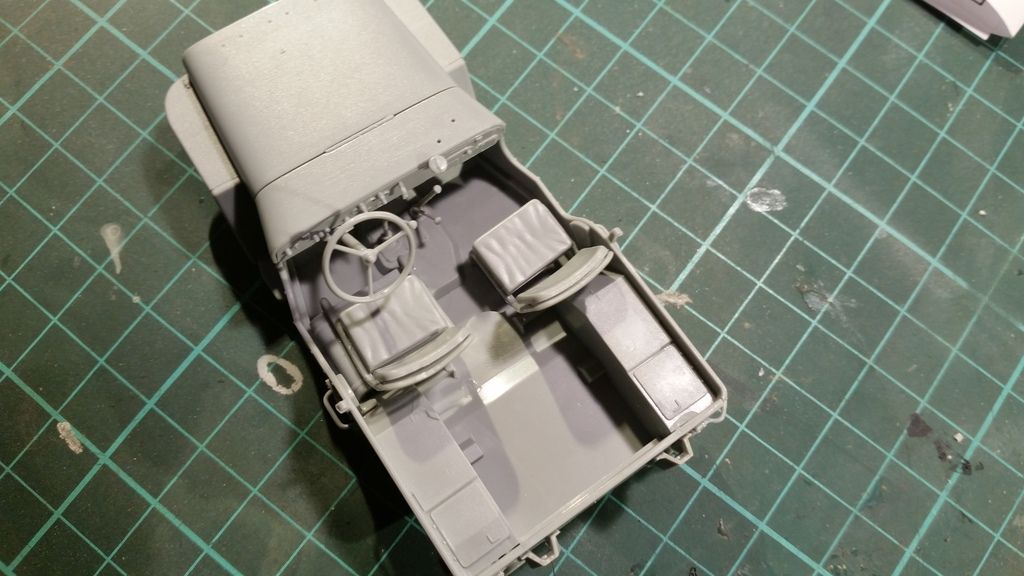

same step but now shown from above

the passenger seat is still out of position but that was fixed after i shot this photo (i noticed it when i made this pic)

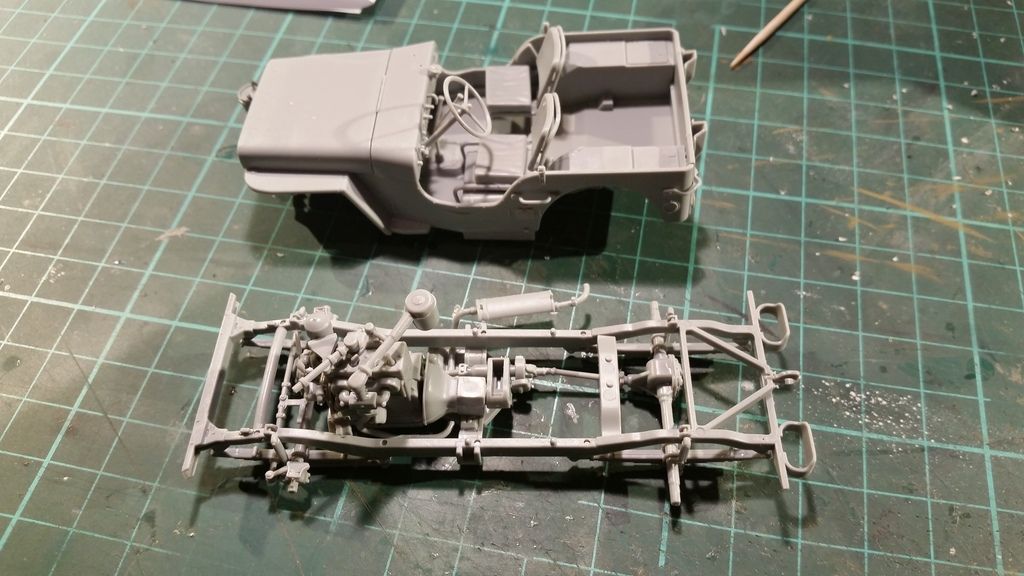

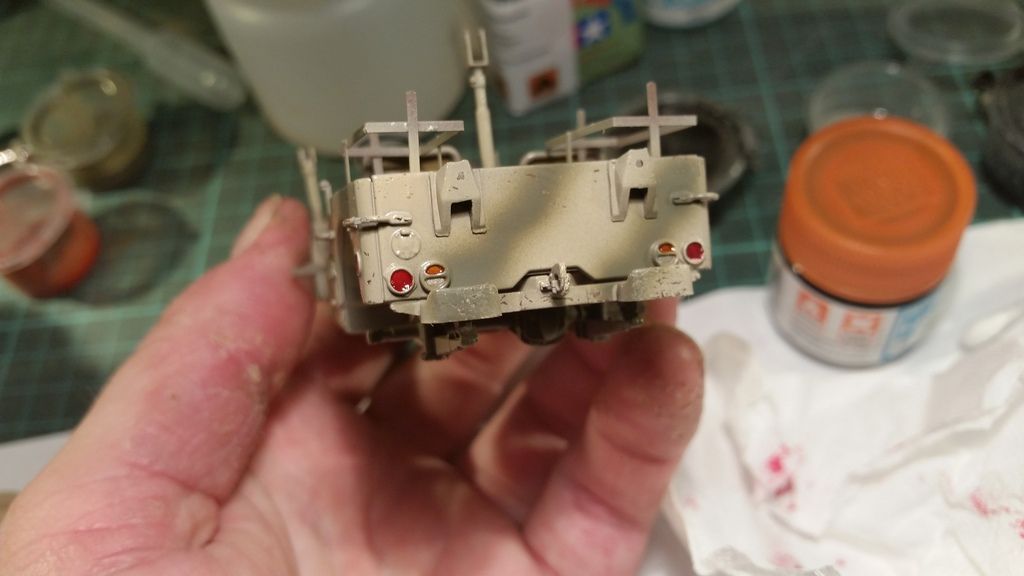

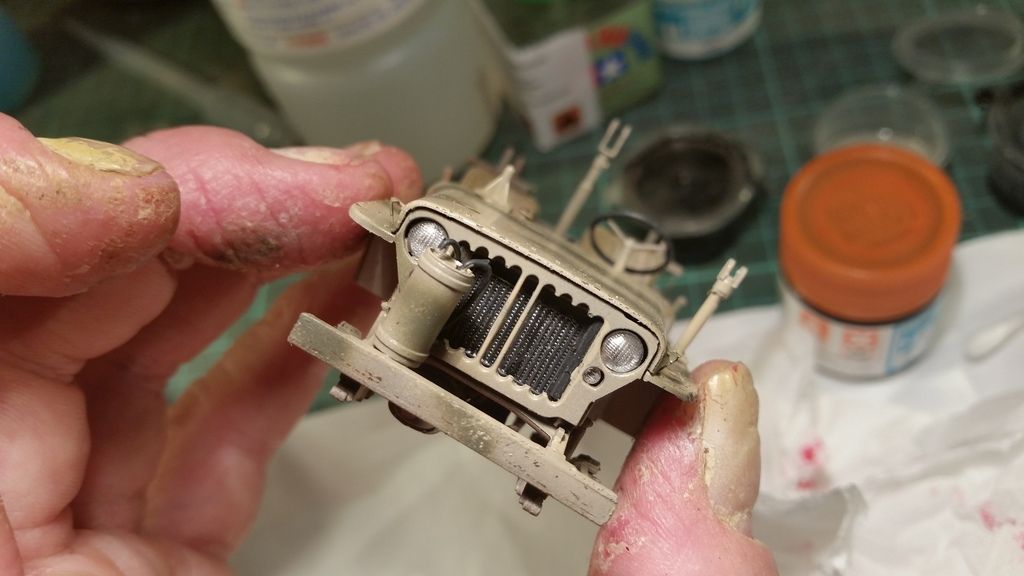

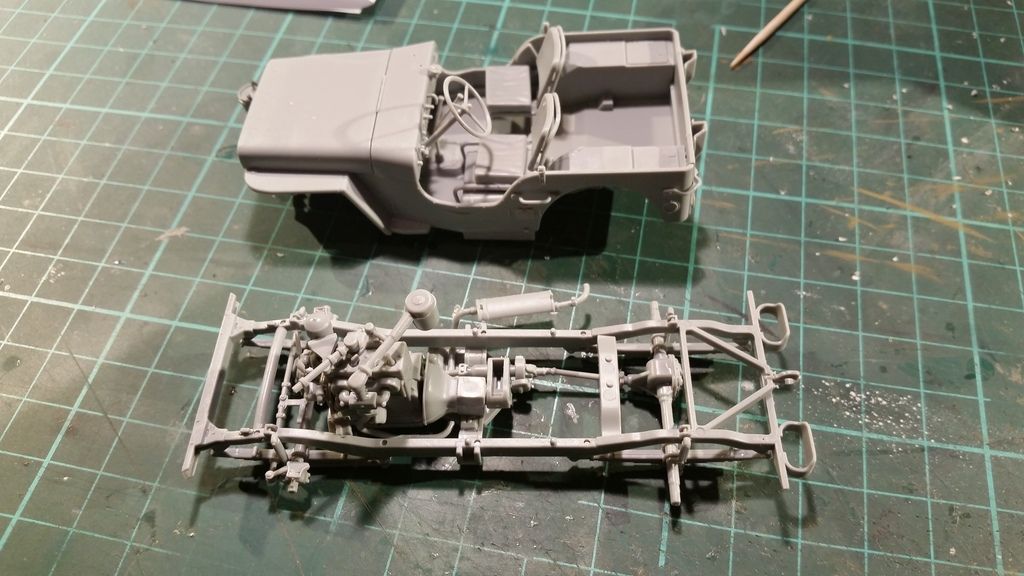

the build up chassis and body

the instruction want you to finish the body first and add all the guns and other details before you join the chassis and body

i think there is too much risk of damaging something so i will do it at this point

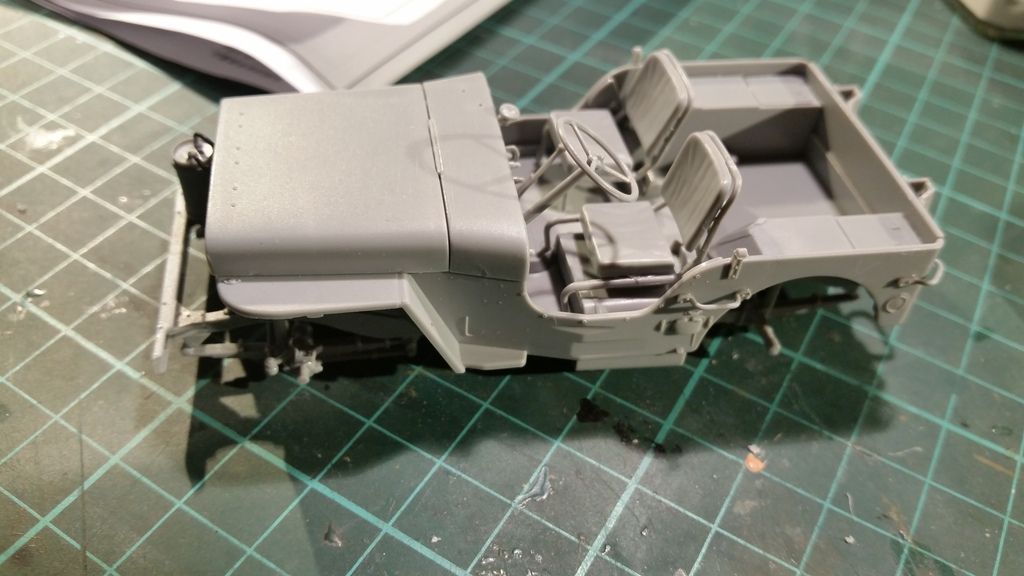

the 2 halfs are joined

this wasn't really a smooth fit so i used a lot of pressure and ca glue to get everything glued together

the gun mounts where added

now all that is left are the guns and stowage

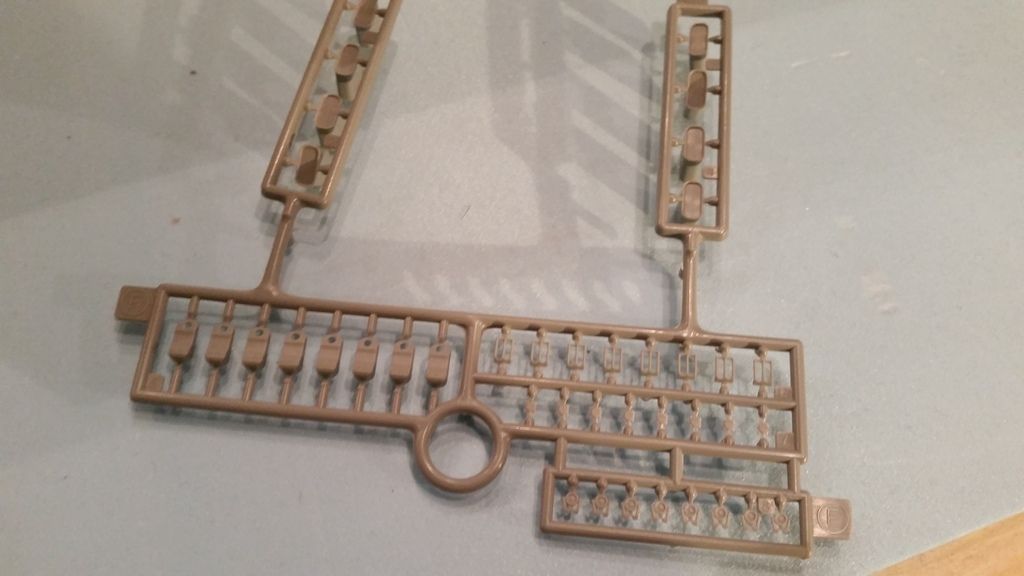

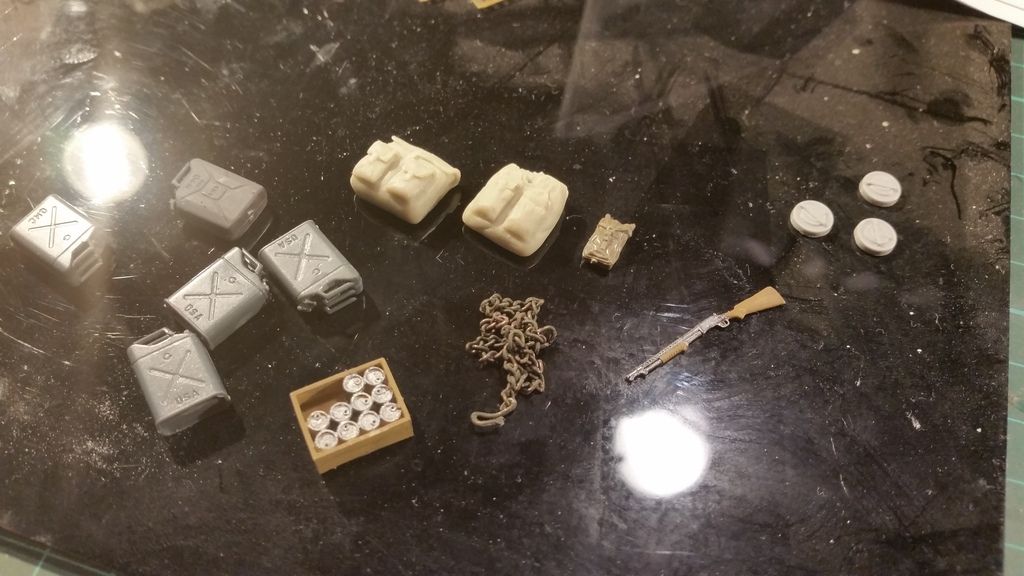

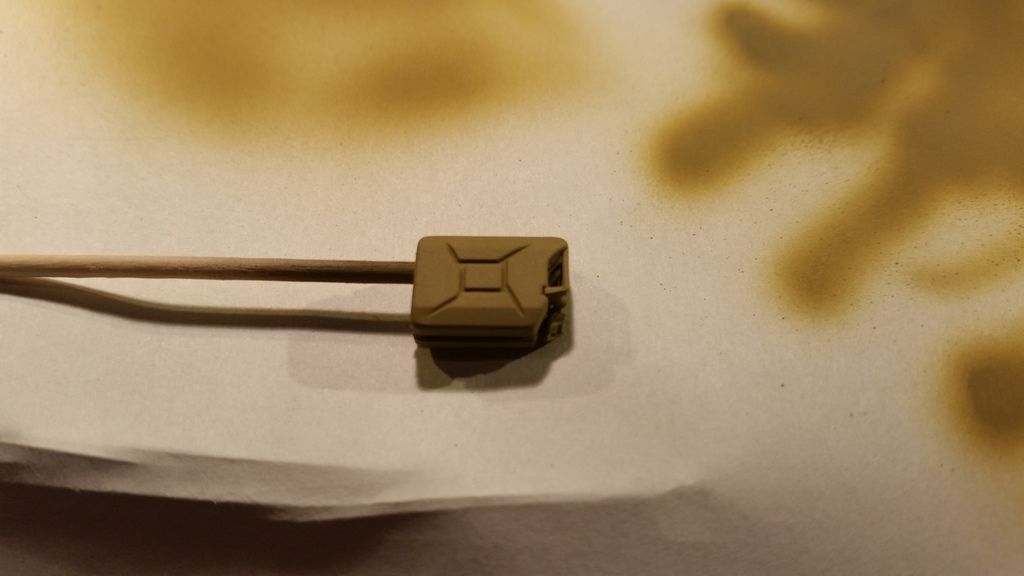

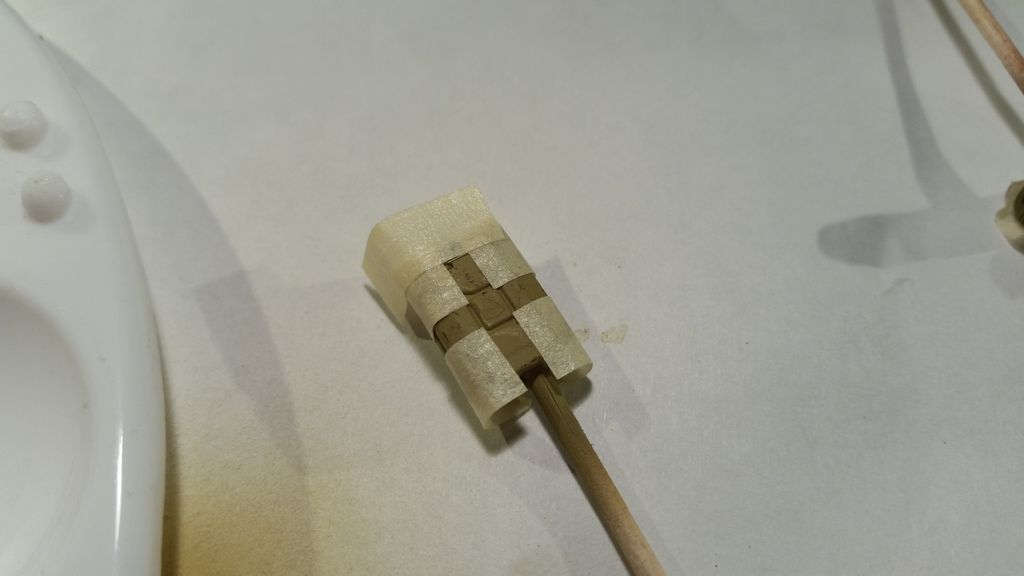

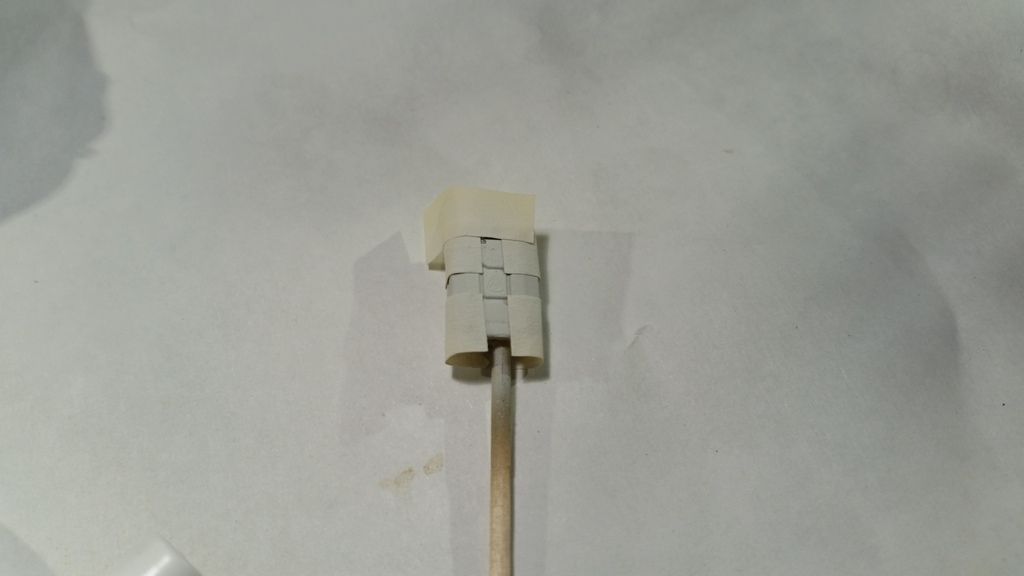

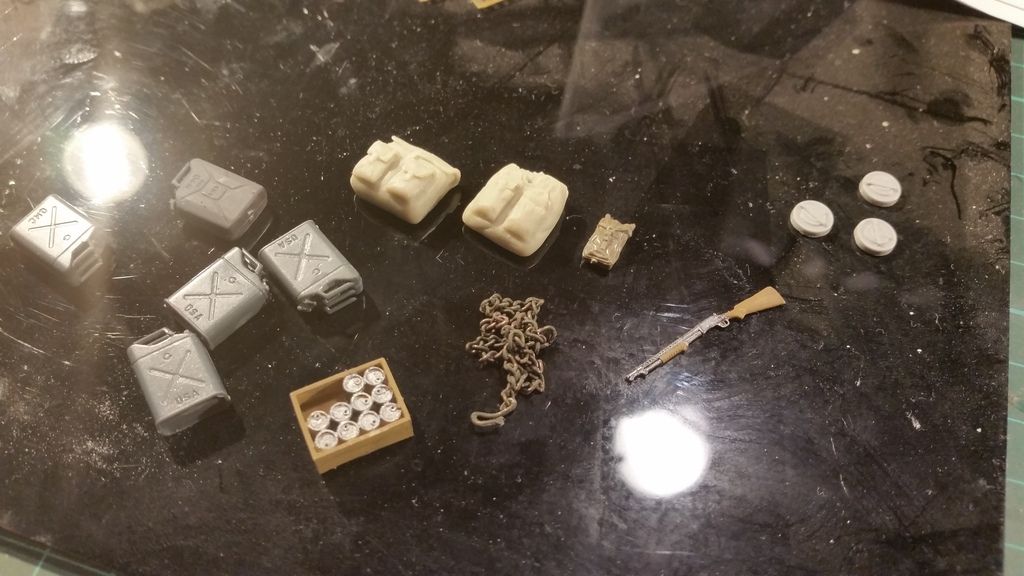

all the parts for the US style jerrycans

and the parts for the German style jerrycans

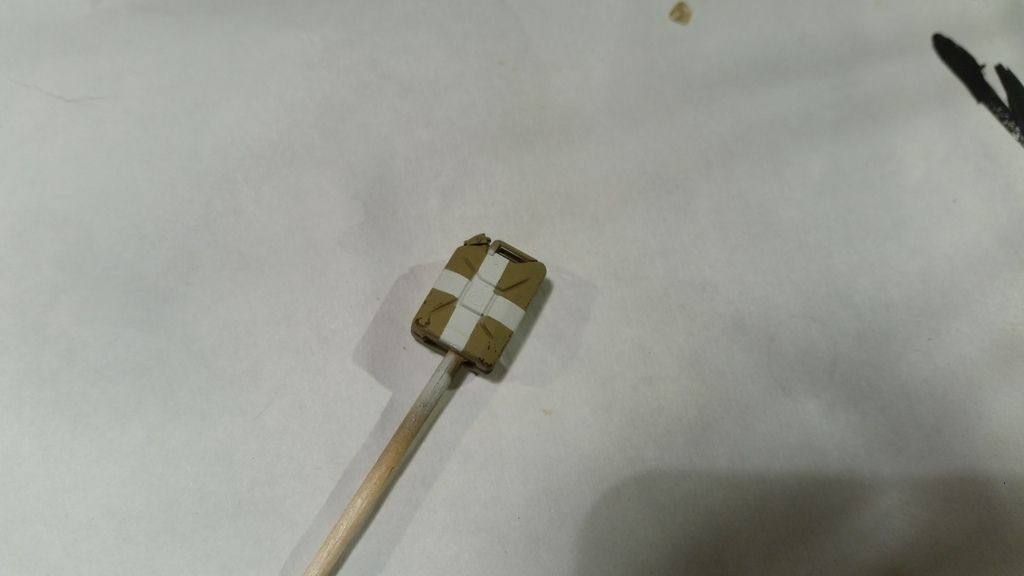

i think they need to look at their design though

they give you styrene parts for 3 cans but pe inserts for 2 , seems a bit dumb to me

the finished jerrycans

i will add the straps later when i glue the cans in position ,this makes it easier to paint and weather them without the risk of spilling paint on already painted parts

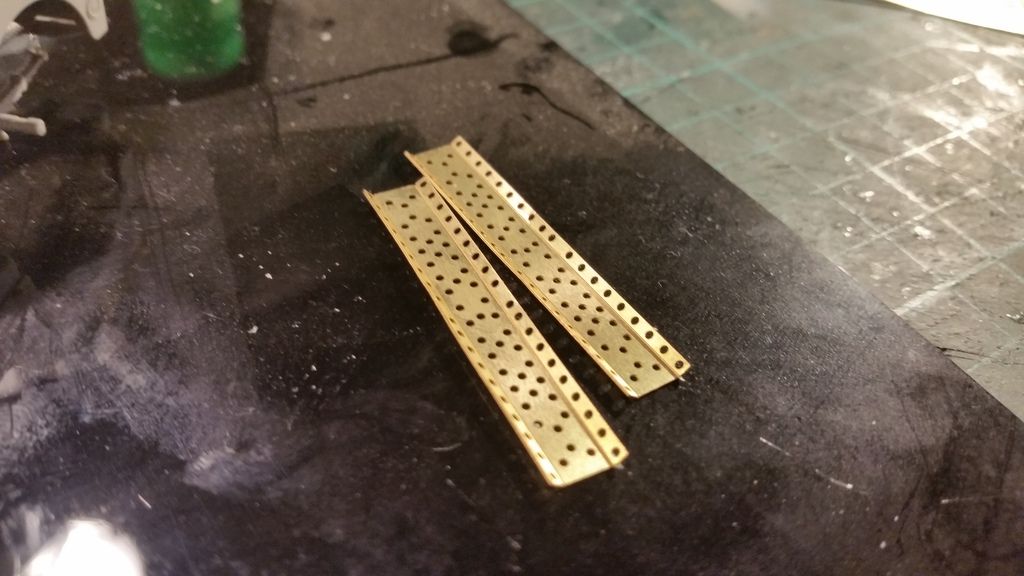

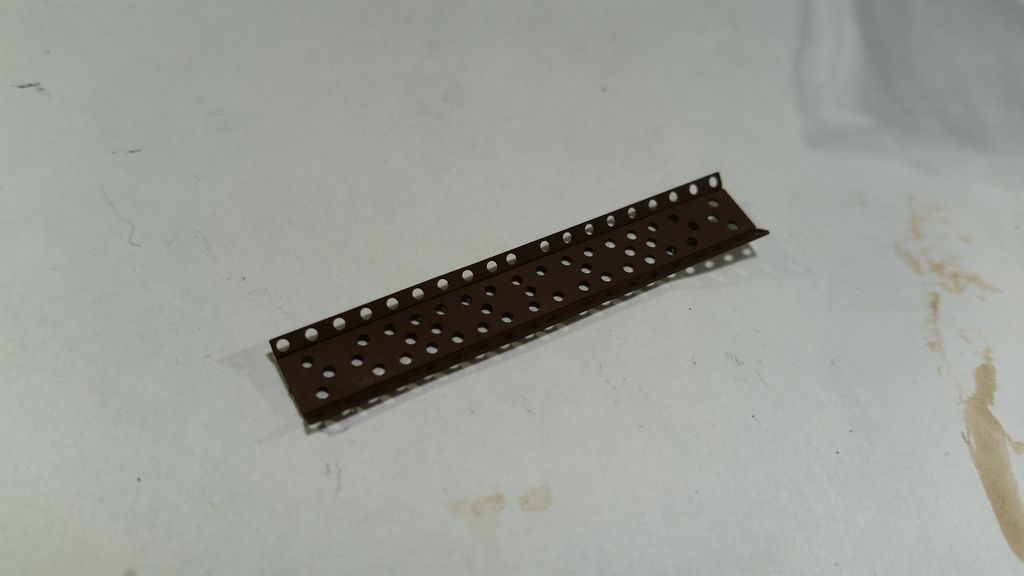

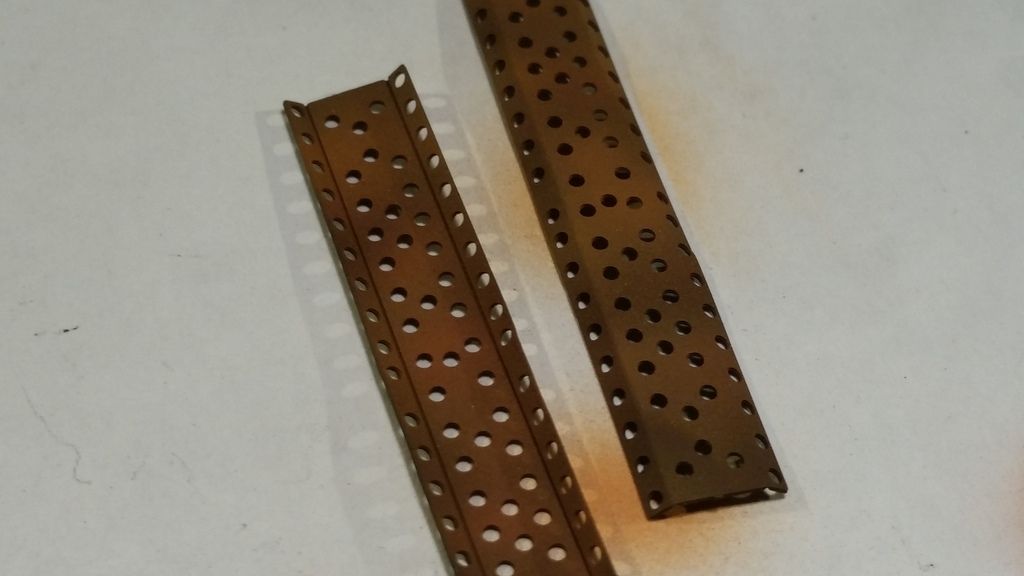

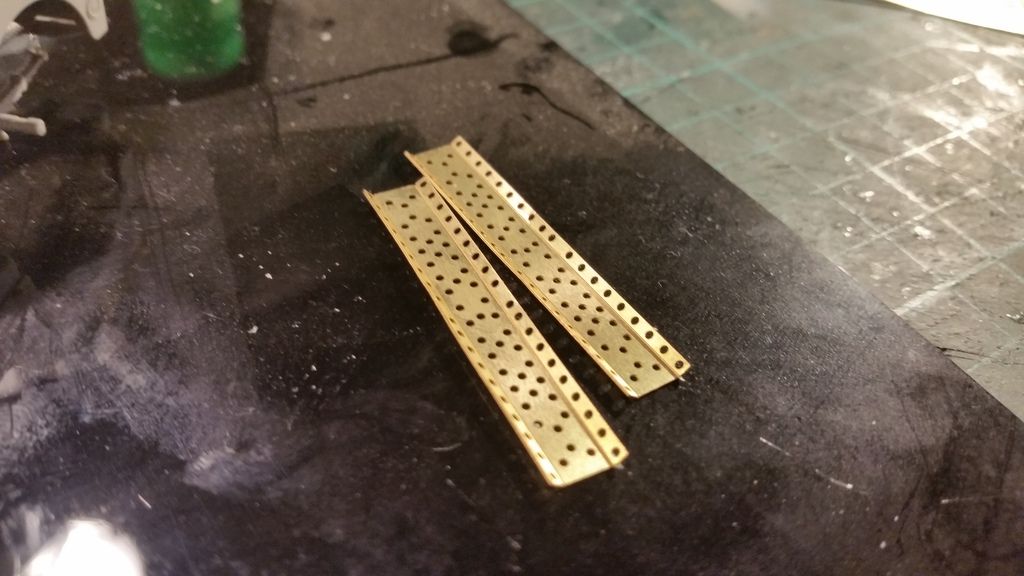

the parts for the jerrycan racks

half way there

there are notches in the parts wich help you to get everything in the right place

the finished racks

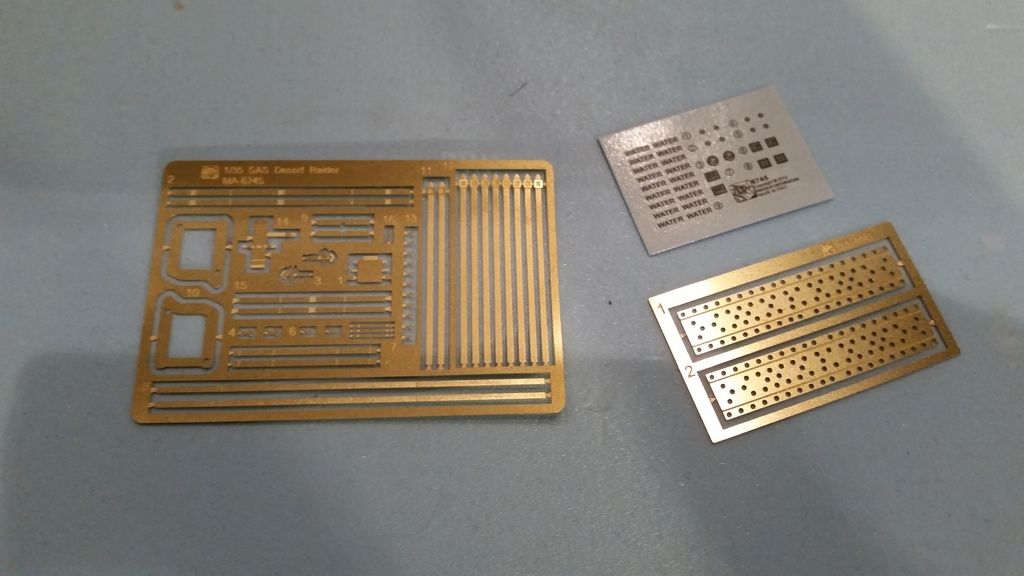

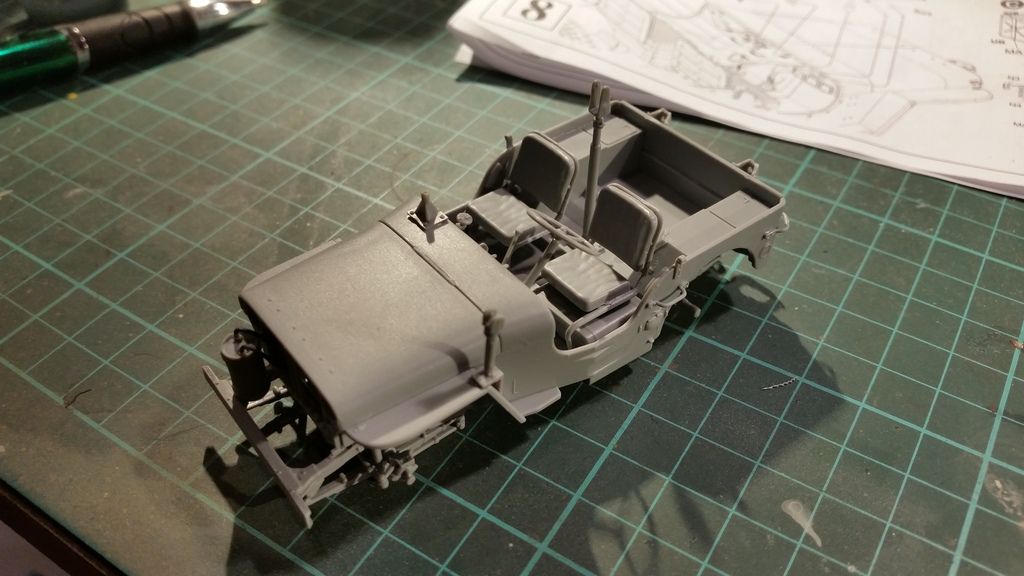

the photo etch details where added , not that much but it adds something to the build and styrene would have looked a bit thick in my opinion

the drive/skid plates are pe and have nothes on the sides where you need to bend them

this works well as you can't over bend them so they will look the right way without a lot of corrections

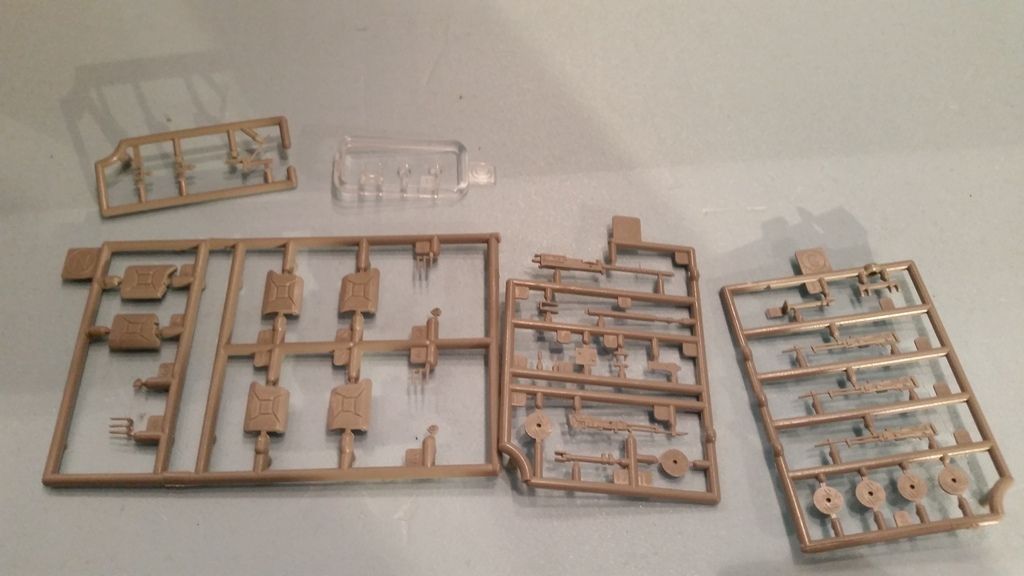

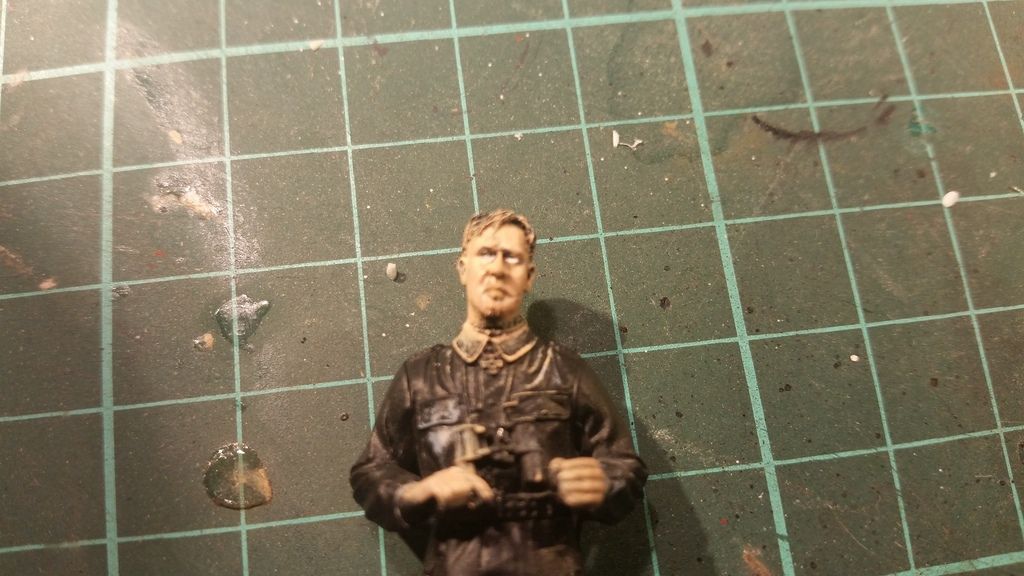

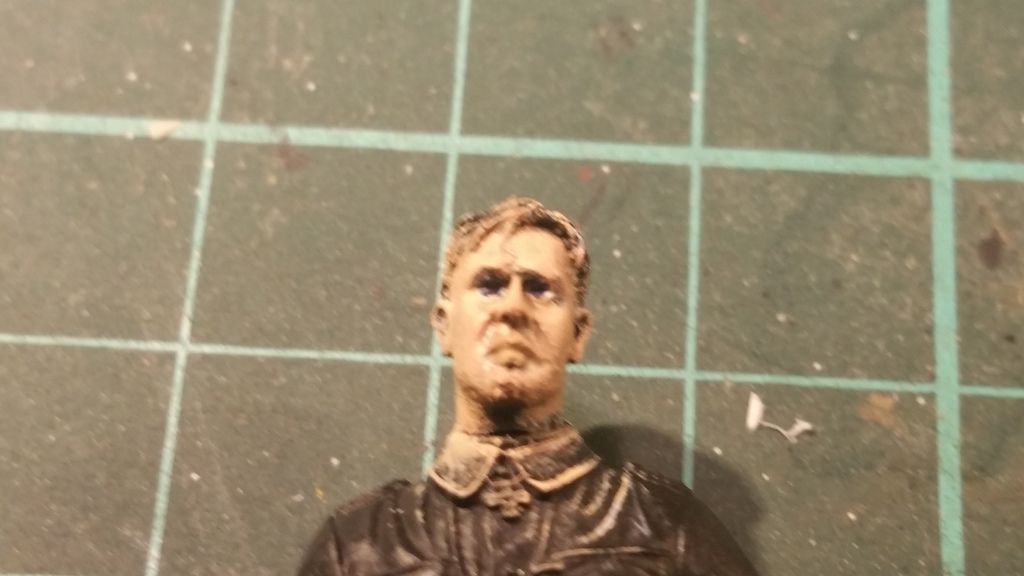

the finished .50 cal Browning

the Vickers K mg's

the other stowage i want to add

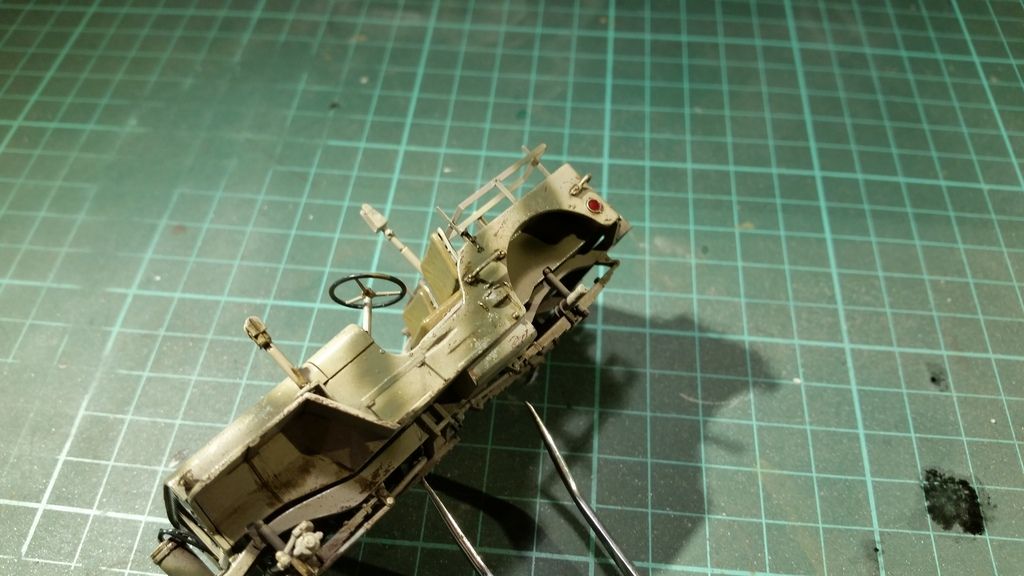

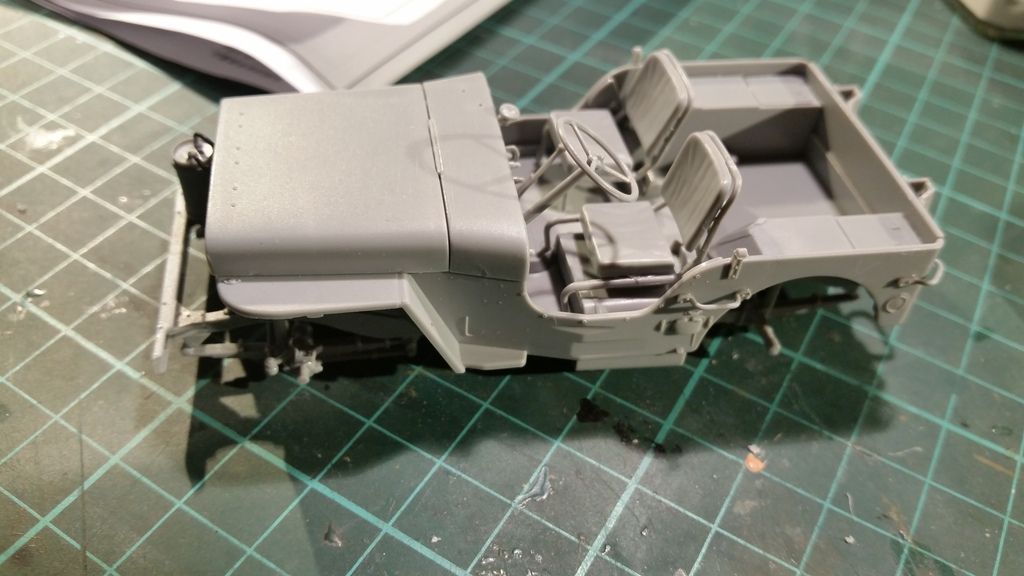

and here are some testfitting shots of how it will be build up after painting

i couldn't place the guns as they are held in place with small pins and i think i will break them when i try to remove the guns for painting so those will be added later

and that is all i have for now

i will have to wait with painting as i cracked the nozzles of my airbrushes

so i will have to get some new ones but the shop i go to is closed as the owners are on vacation but i have more builds on the go so i don't worry about that

i will get back to this as soon as i can

thanks for stopping by and having a look

happy modelling and untill next time

cheers Mark